Felix Doolittle Enamel Pins

︎ Product Design

︎ Project Management

︎ Photo/Color Editing

Felix Doolittle

2022

Overview

During my time as a Junior Graphic Designer at stationer Felix Doolittle, I spearheaded the development of two new product lines—one of which being our first-ever hard enamel pins. This product is part of an initiative to draw a younger audience to the Felix Doolittle brand, whose sensibility typically attracts customers from an older generation. Amid this round of development, our team was able to produce 2 enamel pin sets and one limited edition pin, totaling at 9 hard enamel pins.

Process

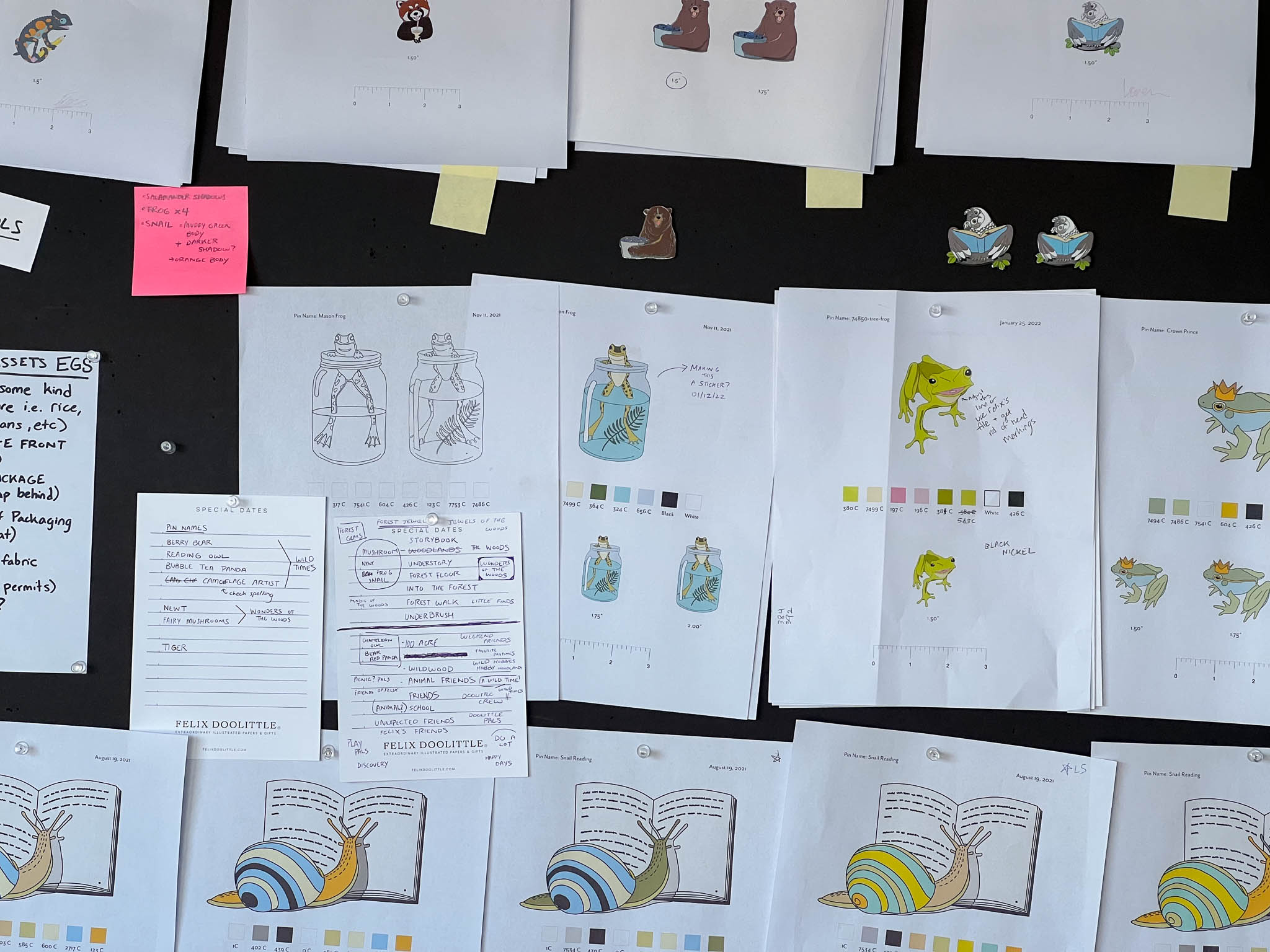

The first step in developing this product was pitching which Felix Doolittle illustrations we would translate into hard enamel pins, and how these illustrations would work together as sets. I took some time to sift through our image library, putting together potential sets of illustrations that I thought would perform well. After presenting around 15 sets, our team worked together to narrow it down to one limited edition pin and 2 final collections—Forest Animals & Woodland Floor.

I put together around 15 potential sets, and we were able to narrow it down to 2 final sets

After our decision, I worked closely with our company’s owner, Felix, to turn his watercolor illustrations into lineart, which we then could send to our pin manufacturer. Felix would trace his illustrations in Photoshop, and afterwards, I took these line drawings and converted them into vector files in Illustrator. Once lineart was finalized, we assigned Pantone colors to each illustration, and sent off our files for our first round of product proofs.

Behind-the-scenes at our color assigning process

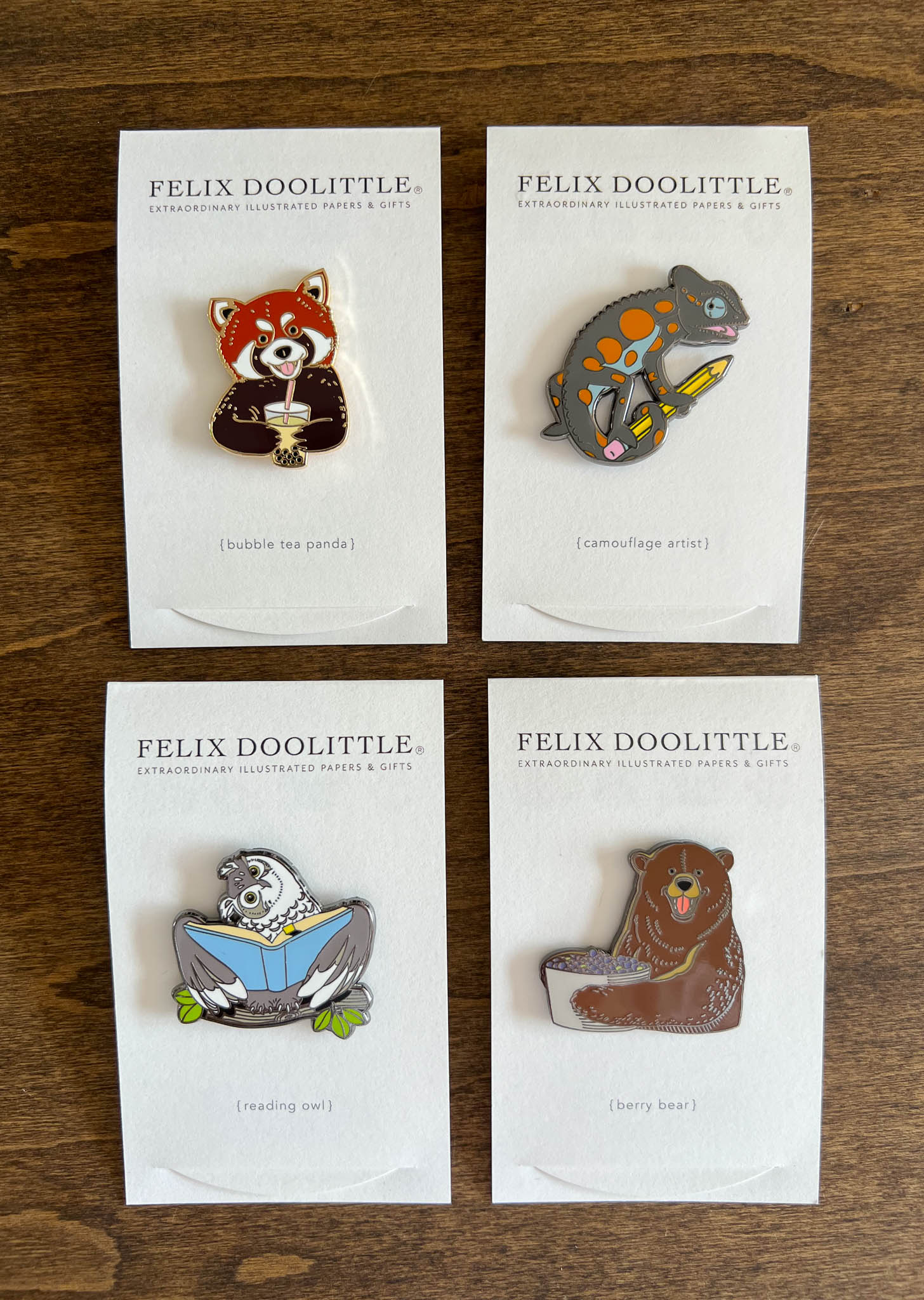

The first product proofs arrived about a month after placing our order. We closely examined these test pins and made our edits, refining the lineart, simplifying our designs, and choosing alternate colors. We then sent our edited files to get a second round of proofs. Once these new pins arrived, we were much more satisfied, and ordered production of the full run.

Our final 9 pins, including our limited edition Year of the Tiger pin

Our journey was not over, however, as we still had to figure out how we could package our new product. At the beginning of this process, our co-owner—Loren—expressed that it would be great if our enamel pin packaging could utilize as little plastic as possible. With this restriction in mind, I developed a few prototypes of all-paper packaging.

I worked on a number of prototypes before finalizing our protective jacket packaging

My final packaging solidified as a folded paper jacket, which could both protect the enamel pin from any scratches during shipping, but also could fold backwards to display the pin in retail stores. The front of this jacket displays Felix’s original illustration, and the packaging seals with a flap and tuck, all without the use of any plastic.

Our final packaging design, complete with illustration on the front flap and full enamel pin set on the back flap

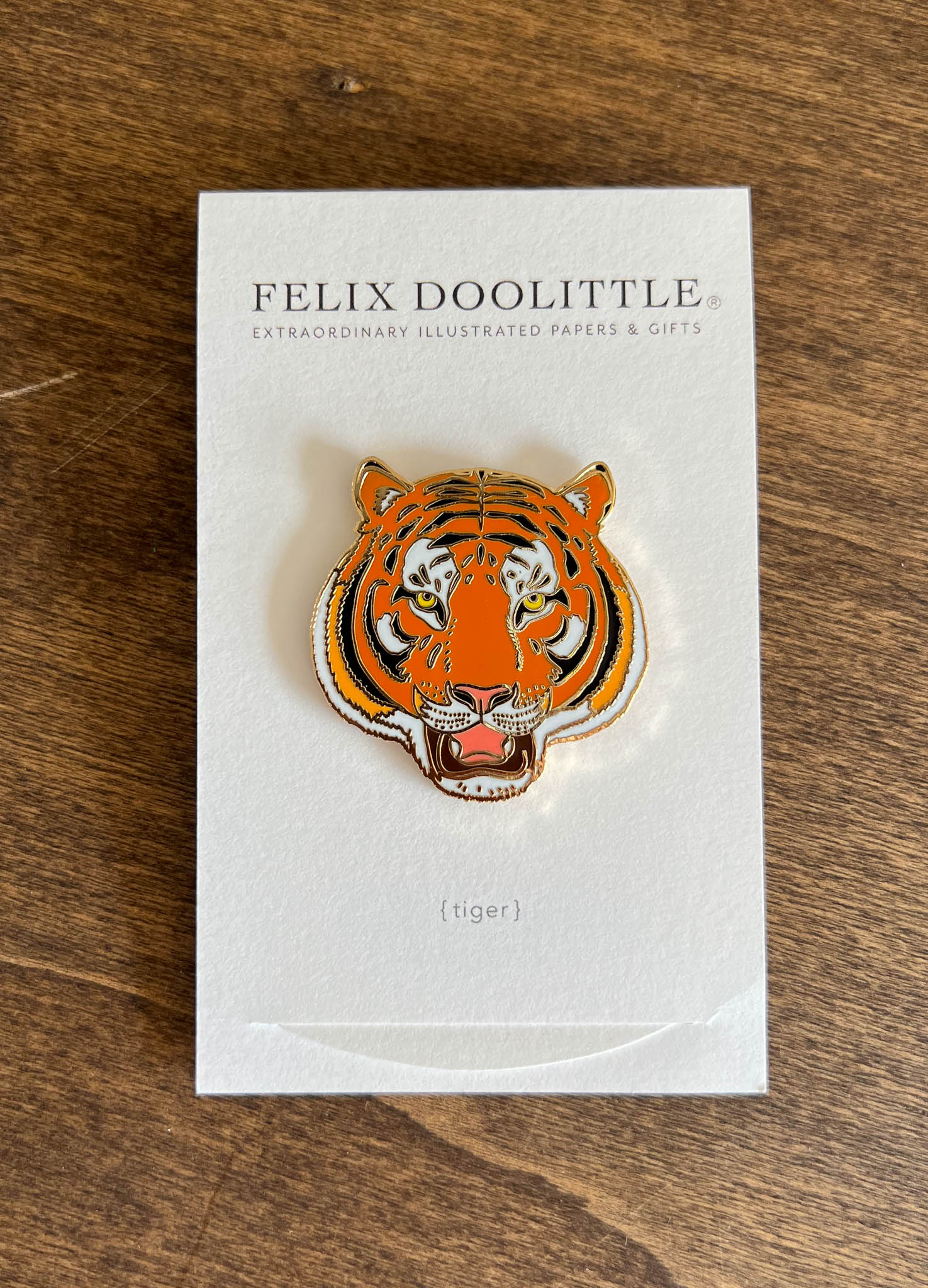

Once we determined the overall structure of the packaging, I had to develop three iterations, one for each of our sets, and one for our limited edition Chinese New Year pin. The first two I was able to design fairly quickly, highlighting the full set of illustrations on the back and including a barcode for easy retail purchase. However, we hit a friction point on our Chinese New Year packaging, struggling to make the pin feel truly limited edition. After bouncing a few ideas back and forth, we did some research and found that our packaging manufacturer could print gold foil—our perfect magic trick. Once we discovered this gold foil, we sent off our full run for proofing.

The gold foil was our secret trick in giving the limited edition packaging a necessary flair

When we received our packaging proofs, we had to tweak a lot of colors in Photoshop to ensure our jackets accurately reflected the colors of Felix’s original watercolor illustrations. It took a few rounds of edits, but we were finally able to get everything looking correct, and successfully ordered a full run on our packaging.

It took a few rounds of proofs before getting the colors just right on our packaging

About a month after placing our orders, our pins and packaging arrived, and it was time for our production team to assemble our product. Assembly was no easy task, as we had to quality check every enamel pin individually, and take a complete inventory. After quality check, we one by one attached each enamel pin to a respective jacket, and after a few days of work, we had our full inventory of pins ready to sell.

The final 9 enamel pins our team launched